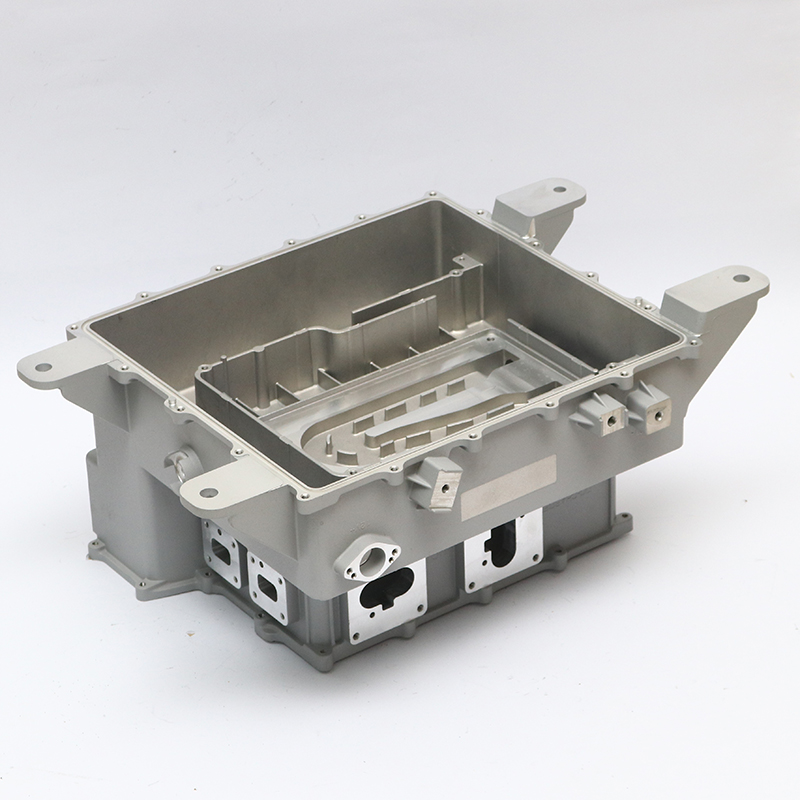

Kev cai Aluminium Alloy Tuag Casting Tsav Controller Housing Motor End Npog rau Lub Tsheb Hluav Taws Xob

Product Description

| Khoom npe: | Electric Tsheb Tsav Xaus Npog |

| Khoom siv: | ADC 12 |

| Specification: | 436.5 * 308 * 200 |

| Daim ntawv pov thawj | ISO9001/IATF16949:2016 |

| Daim ntawv thov: | Automotive |

| Khoom siv tes ua | Aluminium High Pressure tuag casting + CNC machining |

| Nto | Deburring + Tua Blasting |

| Kev tshuaj xyuas | CMM, Oxford-Hitachi spectrometer, Gas nruj tester, Calipers thiab lwm yam |

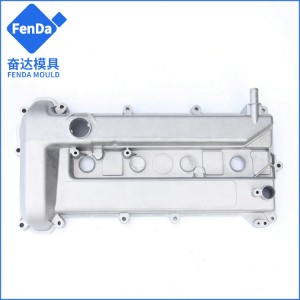

Fenda Kev Cai Tuag Casting Parts

| Cov khoom siv pwm | H13, DVA los yog raws li kev thov |

| Pwm lub neej | 50000 txhaj tshuaj, los yog raws li kev thov |

| Khoom siv | Aluminium alloy ADC12, A360, A380, AlSi12 (Cu), AlSi9Cu3 (Fe), AlSi10Mg thiab lwm yam. |

| Kev kho saum npoo | Polishing, Shotblasting, Sandblasting, Painting, Hmoov txheej |

| Txheej txheem | Drawing & Samples → Pwm ua → Tuag casting → Deburring → Drilling thiab threading → CNC Machining → Polishing → Surface kho → Sib dhos → Kev tshuaj xyuas zoo → Packing → Shipping |

| Tuag casting tshuab | 280T / 400T / 500T / 630T / 800T / 1250T / 1600T / 2000T |

| Kev kos duab | step, dwg, igs, pdf |

| Daim ntawv pov thawj | ISO / TS16949: 2016 |

| QC System | 100% kev soj ntsuam ua ntej pob |

| Muaj peev xwm txhua hli | 40000 pcs |

| Lub sijhawm ua haujlwm | 25 ~ 45 hnub ua haujlwm raws li qhov ntau |

| Cov nqe lus them nqi | T/T |

Vim li cas thiaj xaiv Fenda ua koj tus neeg muag khoom tuag?

1. Tuag Casting Tooling

Cov cuab yeej siv hauv tsev tso cai rau peb ua cov pwm tuag-casting, pwm Fabrication & pwm tu hauv tib lub rhiav.

Peb cov kws tsim pwm pwm yuav tshuaj xyuas koj cov duab kos thiab tawm tswv yim los ntawm kev ntsuas pwm ntws, uas tuaj yeem pab koj tiv thaiv cov teeb meem lossis kev pheej hmoo uas yuav tshwm sim tom qab ntau lawm.

2. Tuag-casting Muaj peev xwm

Fenda yog cov chaw tsim khoom lag luam uas muaj peev xwm nthuav dav qhov tuag casting ntau, nrog cov tshuab tuag casting ntawm 400-2000 tons ntawm cov tonnage sib txawv.Nws tuaj yeem tsim qhov hnyav 5g-20kg.Lub tshuab hluav taws xob ywj pheej ntawm txhua lub tshuab tuag casting ua rau peb muab ntau yam txhuas kom tau raws li qhov tshwj xeeb xav tau ntawm cov neeg siv khoom.

3. CNC Machining Muaj peev xwm

Fenda muaj kev paub dhau los thiab paub tab CNC machining pab pawg, ntau tshaj kaum qhov chaw ua haujlwm txawv teb chaws thiab tshuab dhos, thiab nws tus kheej ua lag luam PTJ khw yog ib qho ntawm kaum lub tuam txhab me me thiab nruab nrab hauv Suav teb.Nws muab txhim khu kev qha precision rau kev ua.Qhov tsawg kawg nkaus kam rau ua yog tswj los ntawm 0.02mm kom tau raws li qhov xav tau ntawm qhov chaw.

4. Kev soj ntsuam zoo

Fenda them nyiaj tshwj xeeb rau kev tswj xyuas qhov zoo ntawm cov txheej txheem ntau lawm thiab tau tsim kom tiav cov txheej txheem tshuaj xyuas zoo thiab cov txheej txheem.Tag nrho cov khoom raug soj ntsuam tag nrho lossis tsim ua raws li cov qauv.Cov khoom siv kuaj muaj xws li: spectrometer, stretching Testing tshuab, CMM peb-coordinate, pass-stop gauge, parallel gauge, ntau yam calipers, thiab lwm yam., kom ua tiav cov kev tswj muaj peev xwm ntawm lub system zoo.

5. Muaj peev xwm kho qhov saum npoo

Fenda tuaj yeem ua tiav qhov kev kho mob ntawm lub cev thiab cov tshuaj txau tshuaj xws li txhaj tshuaj blasting, nplua xuab zeb, hmoov txheej thiab lwm yam.Nyob rau tib lub sijhawm, Fenda tau koom tes nrog cov saw hlau hauv zos rau ntau tshaj 17 xyoo, sib koom ua ke ntawm kaum ob ntawm cov chaw kho mob, thiab los ntawm kev tswj xyuas cov saw hlau sib txuas, muab cov neeg siv khoom kho qhov chaw xws li tshuaj tsuag yas, painting, anodizing, electrophoresis, chrome plating, thiab lwm yam.