Custom High Pressure Aluminium Tuag Casting Pwm Tuag Cast Pwm Rau Nws Pib Parts / Led teeb / Fais Fab Tool / Telecom Part

Cov ntaub ntawv yooj yim

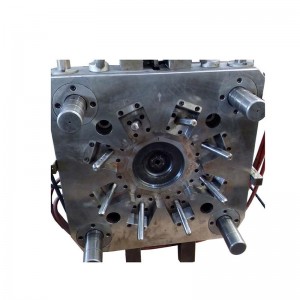

| Khoom npe | High Pressure Tuag Casting Pwm |

| Pwm Khoom | PH13, H13, DVA, DIEVAR, 8407, 8418, W400 thiab lwm yam |

| Casting Alloy | Aluminium |

| Cavity Qty | Tib kab noj hniav, ntau kab noj hniav los yog sib xyaw kab noj hniav |

| Tonnage | 200-2000 T |

| Kev kho mob | Kev kho cua sov, Nitriding, Polishing thiab lwm yam. |

| Pwm Lub Neej | 30000 txhaj tshuaj, 50000 txhaj tshuaj, 80000 txhaj tshuaj nyob ntawm cov khoom |

| Daim ntawv thov | 1. Tsheb qhov chaw; |

| 2. Teeb & teeb qhov chaw; | |

| 3. Cov khoom siv hluav taws xob; | |

| 4. Telecom Parts; | |

| 5. Muaj khoom kho vajtse thiab tshuab Sparepart; | |

| 6. Cov khoom siv hauv tsev; | |

| 7. Cov rooj tog zaum; | |

| Lub Sijhawm Lead | 35-60 hnub |

| Thov tshwj xeeb | Raws li cov neeg siv khoom thov |

Peb yog Aluminium Tuag Casting Pwm Hoobkas, qhov twg koj tuaj yeem tau txais Kev Kub Siab Tuag Casting Tooling uas lav koj cov nyiaj tau los siab tshaj plaws.Peb feem ntau sib txuas lus nrog cov neeg siv khoom ntawm cov ntsiab lus ntawm Pressure Die Casting Moulds, thiab tom qab ntawd ua cov qauv kom txog thaum tus neeg siv khoom txaus siab rau Pressure Die Casting Pwm.

Peb tuaj yeem hloov kho, tab sis tsis txwv rau cov no:

Aluminium tuag casting pib qhov pwm

Aluminium tuag casting telecom vaj tsev pwm

Aluminium tuag casting zog cov cuab yeej pwm

Aluminium tuag casting zog cov cuab yeej vaj tsev pwm

Aluminium tuag casting pib gearbox tsev pwm

Aluminium tuag casting pib dej twj tso kua mis tsev pwm

Aluminium tuag casting lub teeb vaj tsev pwm

Xws li lwm yam Aluminium High Pressure Die Casting cuab yeej.

FENDA Aluminium Tuag Casting Pwm Txheej Txheem

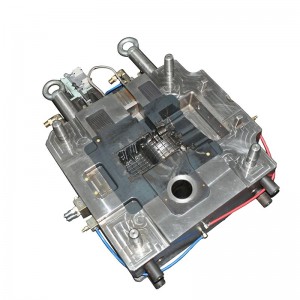

Cov kauj ruam tseem ceeb ntawm peb cov txheej txheem aluminium alloy tuag casting pwm yog: CNC Milling txheej txheem, Kev kho cua sov, EDM txheej txheem, WEDM txheej txheem, polishing, thiab sib dhos

CNC Milling txheej txheem

Thawj kauj ruam ntawm txhuas tuag casting pwm ua: siv cov chaw machining kub ceev los zeb pwm kab noj hniav, tawm hauv machining nyiaj li ntawm ib millimeter rau cov duab ntawm cov khoom.Nws yog rau qee yam deformation tom qab kev kho cua sov.

Tom qab thawj zaug milling, pwm kab noj hniav yuav raug xa mus rau kev kho cua sov.

Thaum cov kab noj hniav rov qab los tom qab kev kho cua sov, kev ua haujlwm thib ob yuav ua tiav.Peb hu cov txheej txheem no zoo machining.Lub sijhawm no, txhua qhov ntau thiab tsawg yog raws li cov pwm tsim duab kos duab

Txheej txheem EDM

Tom qab ob zaug ntawm machining, tseem muaj qee qhov nyuaj rau kev txiav los ntawm kev kub ceev, ces lawv yuav ua tiav los ntawm EDM.

Muaj ntau qhov sib sib zog nqus grooves thiab nqaim slits thiab complex kab noj hniav ntawm pwm nto, uas yog ib qho nyuaj rau txheej txheem nrog milling tshuab.Qhov no yuav tsum tau EDM hluav taws xob tawm machining.

Tsis tas li ntawd, EDM kuj tseem siv rau qee qhov chaw uas xav tau kev ua haujlwm siab tshwj xeeb thiab qhov roughness.

Txheej txheem WEDM

Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm WEDM (xaim txiav) yog siv cov hlau txuas txuas txuas mus ntxiv (hu ua electrode hlau) ua cov khoom siv hluav taws xob los ua cov hluav taws xob hluav taws xob rau ntawm qhov chaw ua haujlwm kom tshem tawm cov hlau thiab txiav rau hauv cov duab.

Lub ejector qhov nyob rau hauv pwm, nrog rau ib co ntse-angled, tshwj xeeb-zoo li tus qhov uas tsis tuaj yeem machined, thiab accessories yog tag nrho ua tiav los ntawm cov hlau txiav.

Tom qab cov txheej txheem no, pwm kab noj hniav yuav polished.Thiab txheej txheem kawg, sib sau cov txhuas tuag casting pwm, thiab sim-tawm.

Fenda Txhuas Tuag Casting Pwm Manufacturing Advantage

Thaum nws los txog rau qhov zoo tshaj plaws kev cai tuag casting pwm txoj kev loj hlob, ob peb influences ua rau tag nrho cov kev vam meej ntawm cov txheej txheem.Fenda muab kev cai txhuas tuag casting pwm tsim cov kev pabcuam rau koj qhov project specifications.Fenda muab cov kev pabcuam tuag casting zoo hauv qab no:

- First Class Engineering

- Cov cuab yeej tuag-casting tsim hauv tsev

- Tswj thiab saib xyuas txhua yam ntawm cov cuab yeej

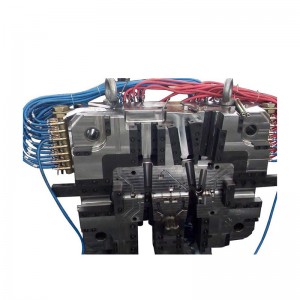

- Tsim cov txheej txheem kev txhaj tshuaj: rooj vag loj, qhov chaw, pub ceev, ntim lub sijhawm, txhaj tshuaj siab, xovxwm loj

- Cov kab sib cais, khiav, hla, qhov cua, cua txias

- Yam tsawg kawg nkaus thiab siab kawg phab ntsa thickness

- Kev xaiv ntawm cov khoom pwm thiab hardness raws li pwm quab yuam xam

- Superior lossis Premium Qib PH13 lossis Dievar

- Flow simulation

- Daim ntawv, radii, fillets

- Tsim kom muaj machining Tshuag

- Kev siv cov cuab yeej siv hauv tsev thiab txawv teb chaws

Hoobkas Profile

Fenda, Tuam Tshoj-raws li txhuas tuag casting chaw tsim tshuaj paus, txaus siab muab cov khoom zoo hauv kev lag luam tuag casting.Los ntawm kev tsim cov cuab yeej siv rau kev tsim khoom, CNC machining, xov, thiab ntim khoom, peb muab cov kev daws teeb meem zoo thiab raug nqi rau tag nrho koj cov kev xav tau ntawm txhuas tuag casting.

- 1-Stop precision txhuas tuag casting tov muab

- 17+ xyoo ntawm kev paub, & 140 tus neeg ua haujlwm

- ISO 9001 & IATF 16949 tau ntawv pov thawj

- 7 Tuag casing tshuab los ntawm 400T txog 2000T.

- 80+ high-speed / high-precision machining chaw

- 30 teeb ntawm high-precision do txhuam vuam, kho deg thiab lwm yam precision tshwj xeeb tshuab

- 1 teeb ntawm Zeiss CMM, 1 teeb ntawm Eduard CMM, 1 teeb ntawm kev lag luam CT, 1 txheej ntawm Oxford-Hitachi spectrometer thiab ob peb txheej roj nruj testers.

Nrog cov kev daws teeb meem tig, pab pawg kws tshaj lij, thiab kev cog lus kom xa cov khoom lag luam zoo thiab cov kev pabcuam zoo, peb pab koj txuag nqi thiab khiav koj cov haujlwm kom zoo dua.Tiv tauj peb rau koj qhov project tom ntej.