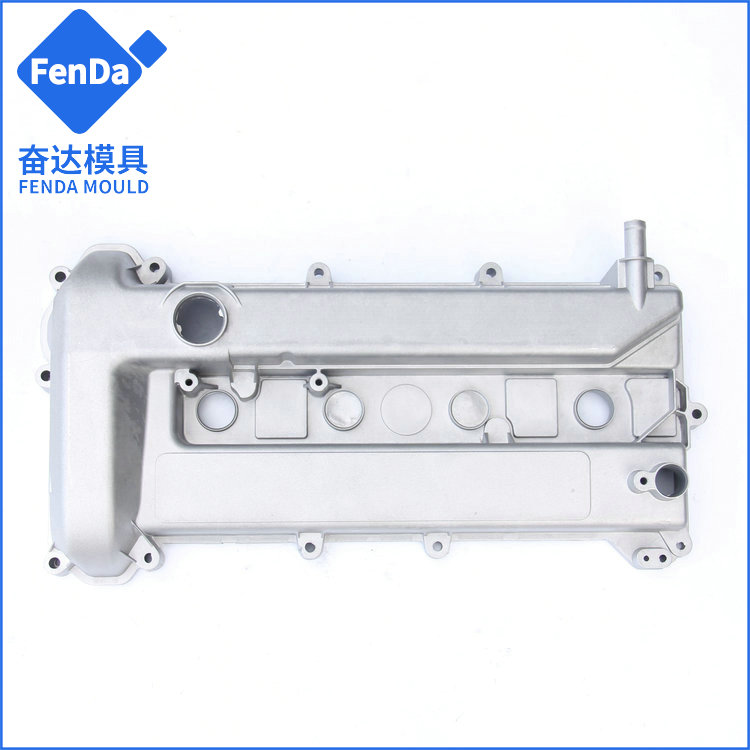

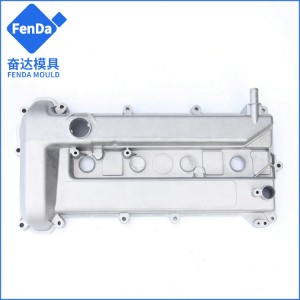

OEM Aluminium Auto Parts Tuag Casting Tsav Tsev Lub tog raj kheej Lub taub hau Lub Tsev / Npog

CYLINDER HEAD COVER

Peb lub tog raj kheej lub taub hau npog yog ua los ntawm aluminium alloy.Feem ntau, aluminium alloy yog sib dua thiab muaj zog cua sov dissipation muaj peev xwm tshaj lwm yam khoom.Meanwhile, Vim li cas xaiv aluminium alloy los ua cov khoom ntawm lub tog raj kheej lub taub hau valve npog?Tsis tsuas yog txhuas lub tog raj kheej lub taub hau npog tuaj yeem txo qhov hnyav ntawm lub tsheb, tab sis kuj txhim kho cov cua kub dissipation ntawm lub cav.Lub tog raj kheej lub taub hau npog pab txhawm rau kaw lub tog raj kheej lub taub hau qhov chaw los ntawm sab nraud ntawm lub cav.Raws li qhov tshwm sim ntawm kev ua haujlwm ntawm lub tshuab hluav taws xob sab hauv, lub tshuab hluav taws xob los ntawm cov txheej txheem combustion thiab cov roj tee los ntawm lub tshuab lubricant ntawm lub cav muaj nyob rau hauv lub tog raj kheej taub hau.

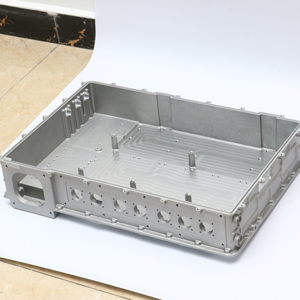

Fenda Aluminium Alloy Tuag Casting & CNC

| Txheej txheem

| Drawing & Samples → Pwm ua → Tuag casting → Deburring → Drilling thiab threading → CNC Machining → Polishing → Surface kho → Sib dhos → Kev tshuaj xyuas zoo → Packing → Shipping |

| Khoom siv | Txias chamber kab rov tav tuag casting tshuab 400T-2000T.CNC chaw, EDM, WEDM, high-precision do txhuam vuam tshuab, CNC Milling tshuab, CNC Drilling tshuab, CNC tig tshuab, CNC sib tsoo tshuab, CMM, Oxford-Hitachi spectrometer, Gas nruj tester |

| Khoom siv | Aluminium alloy ADC12, A360, A380, AlSi12 (Cu), AlSi9Cu3 (Fe), AlSi10Mg thiab lwm yam. |

| Nto | Trimming, Deburring, Polishing, Shotblasting, Sandblasting, Painting, Hmoov txheej |

| Software Assistance | Pro-e/Solid work/UG/Auto CAD/CATIA |

| Daim ntawv thov khoom | Automotive Kev Lag Luam, Led teeb pom kev zoo, Kev sib txuas lus, Textile machinery, Rooj tog, Fais fab cuab yeej, Kub dab dej, lwm yam machinery industries. |

Hoobkas Profile

Fenda, Tuam Tshoj-raws li txhuas tuag casting chaw tsim tshuaj paus, muaj cov khoom zoo nyob rau hauv tuag casting kev lag luam.Los ntawm kev tsim cov cuab yeej siv rau kev tsim khoom, CNC machining, xov, thiab ntim khoom, peb muab cov kev daws teeb meem zoo thiab raug nqi rau tag nrho koj cov kev xav tau ntawm txhuas tuag casting.

- 1-Stop precision txhuas tuag casting tov muab

- 15+ xyoo ntawm kev paub, & 140 tus neeg ua haujlwm

- ISO 9001 & IATF 16949 tau ntawv pov thawj

- 7 Tuag casing tshuab los ntawm 400T txog 2000T.

- 80+ high-speed / high-precision machining chaw

- 30 teeb ntawm high-precision do txhuam vuam, kho deg thiab lwm yam precision tshwj xeeb tshuab

- 1 teeb ntawm Zeiss CMM, 1 teeb ntawm Eduard CMM, 1 teeb ntawm kev lag luam CT, 1 txheej ntawm Oxford-Hitachi spectrometer thiab ob peb txheej roj nruj testers.

Lub taub hau lub tog raj kheej feem ntau yog nyob rau sab saum toj ntawm lub cav thaiv.Nws ua haujlwm raws li lub tsev rau cov khoom xws li cov khoom noj thiab cov pa tawm, cov springs thiab lifters thiab combustion chamber

Qhov zoo ntawm peb cov txheej txheem casting

1. Kaw Siab

Peb cov castings yog tsim nyob rau hauv hlau pwm yog li qhov sib txawv ntawm ib thooj mus rau ib daim yog negligible thiab nyob ze rau kev kam rau siab yog tsis tu ncua.Peb lub peev xwm ua tiav qhov raug siab tshaj plaws thiab qhov tseeb tau tso cai rau peb kom ua tiav ntau qhov chaw uas tau siv yam tsis siv lub tshuab, ua rau muaj txiaj ntsig zoo rau peb cov neeg siv khoom.

2. Zoo heev

Kev tswj cov txheej txheem thiab kev ua haujlwm pem hauv ntej yog cov yuam sij kom lav qhov zoo tshaj plaws castings.Qhov no tej zaum yog vim li cas Fenda tshaj cov qauv kev lag luam rau sab hauv seem thiab tsis ua hauj lwm.Hauv cov ntsiab lus, Fenda siv zog rau Zero-Defects los ntawm kev soj ntsuam tas li txhua qhov kev ua haujlwm thiab nqis peev rau kev mob siab rau hauv kev txhim kho thiab tsim cov cuab yeej.

3. Cov duab tsis yooj yim

Peb cov pwm yog machined los ntawm cov hlau qib siab.Raws li pov thawj los ntawm cov casting saum toj no, cov duab nyuaj nrog cov phab ntsa nyias tuaj yeem raug cam khwb cia siv cov txheej txheem coring ingenious yog li tsis xav tau kev siv tshuab.Undercuts niaj hnub nrum nrog kev siv cov xuab zeb cores, thiab qee zaum, txawm tias tsis muaj.Ua tiav cov kab noj hniav, cov txheej txheem sib txuas sib txuas, thiab lub xeev-ntawm-lub-kos duab molding ua cov txhuas qhov chaw ua haujlwm niaj hnub rau Fenda.